Polyvinyl chloride (PVC) is a polymer made by the polymerization of vinyl chloride monomer (VCM) in the presence of initiators such as peroxides and azo compounds or by the mechanism of free radical polymerization under the action of light or heat. PVC is a polymer material that uses a chlorine atom to replace a hydrogen atom in polyethylene, and vinyl chloride homopolymers and vinyl chloride copolymers are collectively called vinyl chloride resins.

PVC molecular chains contain strongly polar chlorine atoms with high intermolecular forces, which make PVC products more rigid, hard, and mechanically sound, and have excellent flame retardancy (flame retardancy refers to the property that a substance has or that a material has after treatment to significantly delay the spread of flame); however, its dielectric constant and dielectric loss angle tangent values are larger than those of PE.

PVC resin contains a small number of double bonds, branched chains and initiator residues left in the polymerization reaction, plus the chlorine and hydrogen atoms between the two adjacent carbon atoms, which are easily dechlorinated, resulting in the degradation reaction of PVC easily under the action of light and heat. Therefore, PVC products need to add heat stabilizers, such as calcium-zinc heat stabilizer, barium-zinc heat stabilizer, lead salt heat stabilizer, organic tin stabilizer, etc.

Main applications

PVC comes in different forms and can be processed in a variety of ways, including pressing, extruding, injecting, and coating. PVC plastics are commonly used in the manufacture of films, artificial leather, insulation of wires and cables, rigid products, flooring, furniture, sports equipment, etc.

PVC products are generally classified into 3 categories: rigid, semi-rigid and soft. Rigid and semi-rigid products are processed without or with a small amount of plasticizer, while soft products are processed with a large amount of plasticizer. After adding plasticizers, the glass transition temperature can be lowered, which makes it easier to process at a lower temperature and increases the flexibility and plasticity of the molecular chain, and makes it possible to make soft products that are flexible at room temperature.

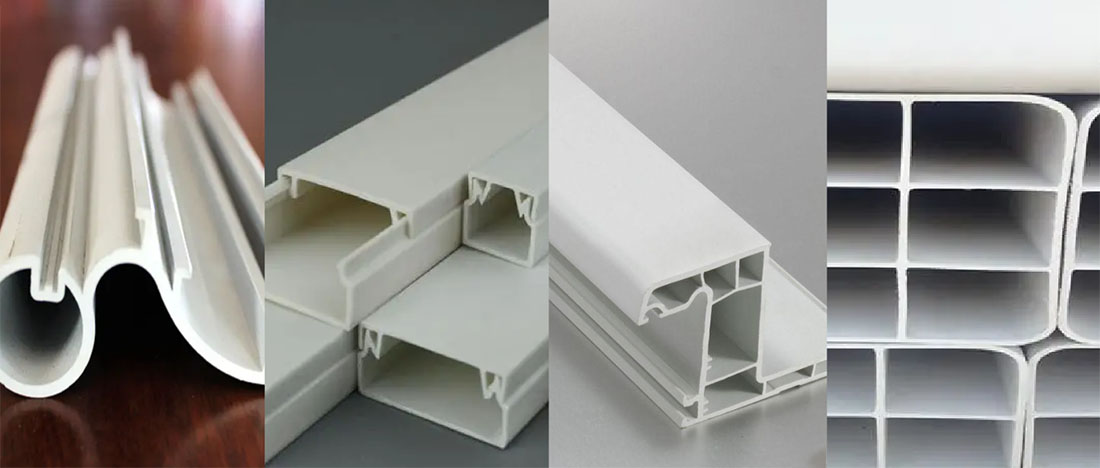

1. PVC profiles

Mainly used for making doors and windows and energy-saving materials.

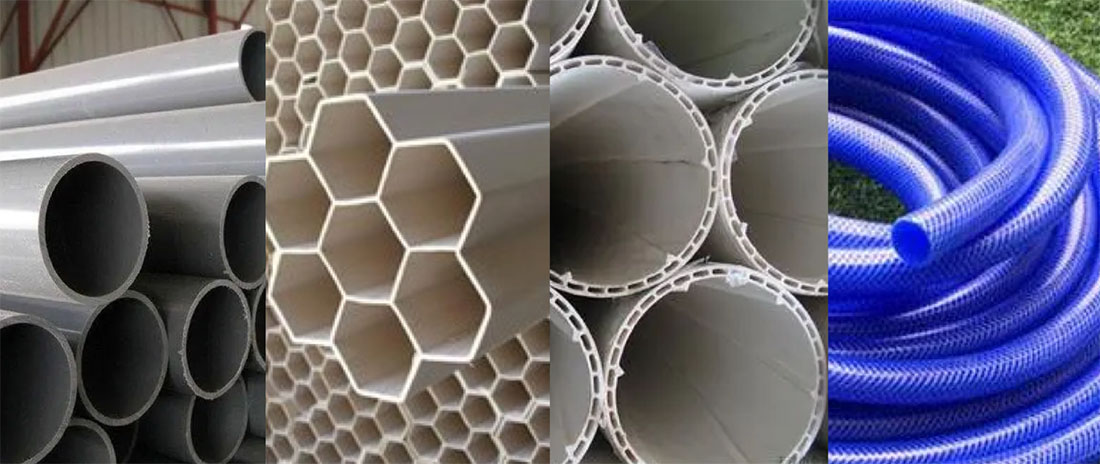

2. PVC pipes

PVC pipes have many varieties, excellent performance and wide range of use, and occupy an important position in the market.

3. PVC films

PVC can be made into transparent or colored film of specified thickness by using calendar, and the film produced by this method is called calendered film. PVC granular raw materials can also be blown into film using blow molding machines, and the film produced by this method is called blow molding film. The film can be used for many purposes and can be processed into bags, raincoats, tablecloths, curtains, inflatable toys, etc. by cutting and heat-sealing methods. Wide transparent films can be used to build greenhouses and plastic greenhouses, or used as floor films.

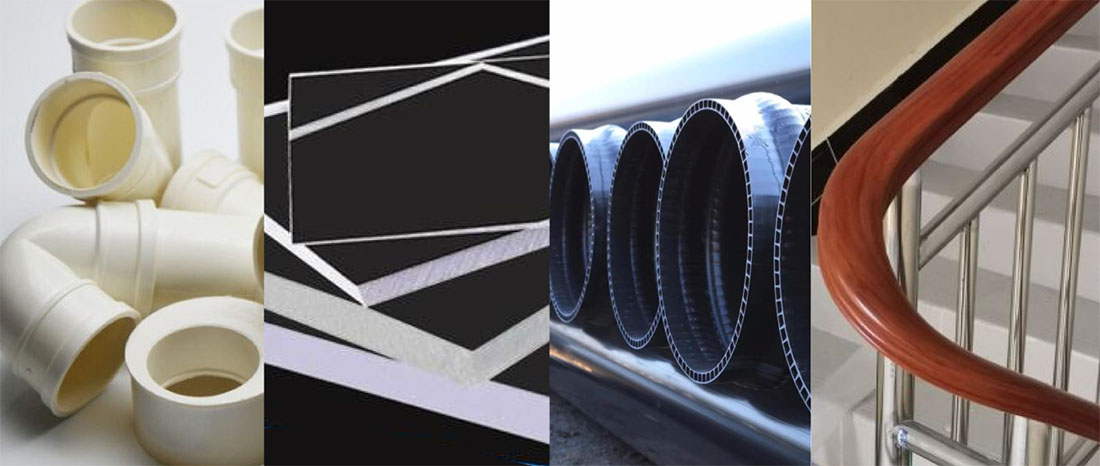

4. PVC board

Added with stabilizer, lubricant and filler, and after mixing, PVC can be extruded into various caliber hard pipes, shaped pipes and corrugated pipes with extruder, and used as downpipe, drinking water pipe, electric wire casing or staircase handrail. The calendered sheets are overlapped and hot pressed to make rigid sheets of various thicknesses. The sheets can be cut into desired shapes and then welded with hot air using PVC welding rods into various chemical-resistant storage tanks, ducts and containers, etc.

5. PVC soft products

Using the extruder, it can be extruded into hoses, cables, wires, etc.; using the injection molding machine with various molds, it can be made into plastic sandals, shoe soles, slippers, toys, auto parts, etc.

6. PVC packaging materials

PVC products for packaging mainly for a variety of containers, film and hard sheet. PVC containers are mainly produced for mineral water, beverages, cosmetic bottles, but also for refined oil packaging.

7. PVC siding and flooring

PVC siding is mainly used to replace aluminum siding, PVC floor tiles, except for a part of PVC resin, the rest of the components are recycled materials, adhesives, fillers and other components, mainly used in the airport terminal floor and other places of hard ground.

8. PVC consumer products

PVC products can be found everywhere in our daily life. PVC is used to make various artificial leathers for luggage bags, sports products such as basketballs, soccer balls and rugby balls. It is also used to make uniforms and special protective equipment belts. PVC fabrics for apparel are generally absorbent fabrics (no coating required) such as ponchos, baby pants, artificial leather jackets and various rain boots. PVC is also used in many sports and entertainment products such as toys, records and sporting goods.

Post time: Jul-19-2023