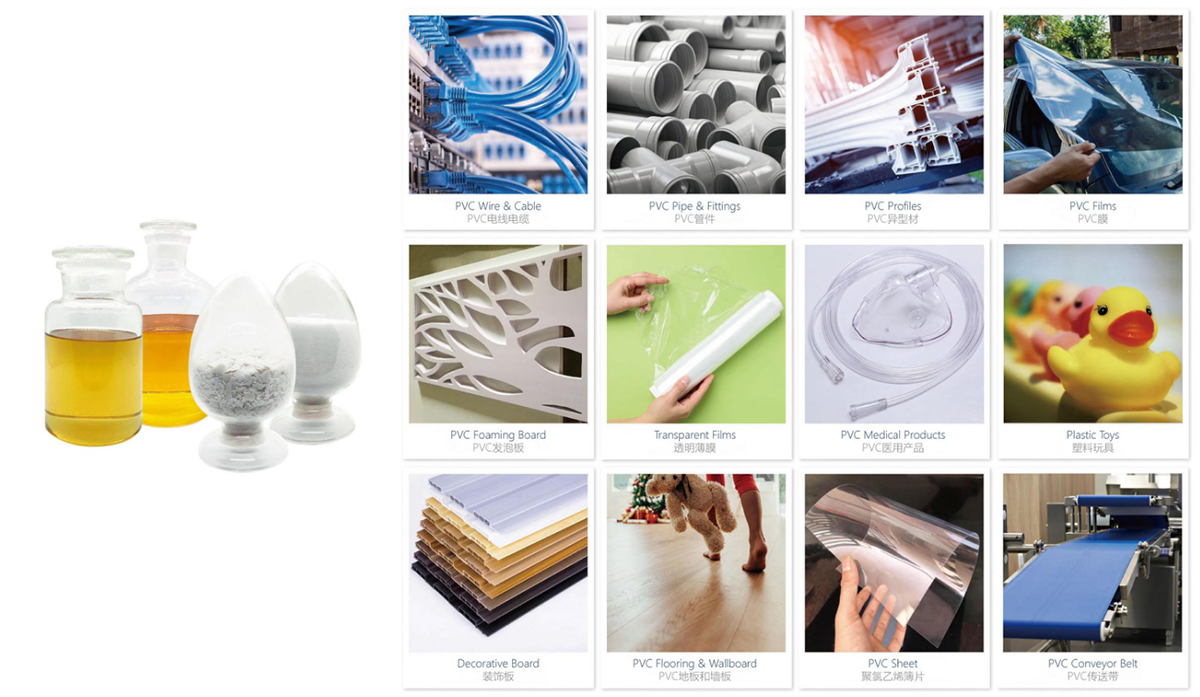

PVC stands for polyvinyl chloride and is a versatile material used extensively in manufacturing. It is commonly used in the production of pipes, cables, clothing and packaging, among many other applications. One of the key ingredients that ensures the durability and performance of PVC products is PVC stabilizers.

PVC stabilizers are additives mixed with PVC during the PVC production process to prevent material degradation caused by heat, UV rays and other environmental factors. This is essential to ensure that PVC products have a longer shelf life and can withstand the rigors of daily use.

There are different types of PVC stabilizers, each designed to solve specific challenges. For example, heat stabilizers are used to protect PVC from high temperatures, while UV stabilizers help prevent the material from degrading when exposed to sunlight. Other types of stabilizers include lubricants, impact modifiers and processing aids, all of which play a role in improving the performance and service life of PVC products.

In the construction industry, PVC stabilizers are particularly important to ensure the durability of PVC pipes and fittings. These products are commonly used in piping systems that are exposed to a wide range of temperatures and pressures. Without the proper stabilizers, PVC pipes can become brittle and crack easily, causing leaks and potentially expensive repairs.

Likewise, in the automotive industry, PVC stabilizers are used in the production of cables and wire harnesses. These components are often affected by heat and vibration, and the presence of stabilizers ensures that PVC insulation remains intact and reliable throughout the life of the vehicle.

In the consumer goods sector, PVC stabilizers also play a vital role. From vinyl flooring to window frames, PVC is a popular choice because of its durability and low maintenance requirements. By incorporating stabilizers during the manufacturing process, these products maintain their appearance and functionality for years, even in challenging environments.

It is worth noting that the use of PVC stabilizers is also guided by regulatory standards to ensure the safety and environmental impact of PVC products. For example, certain types of stabilizers, such as lead-based stabilizers, are being phased out in many areas due to concerns about their toxicity. As a result, manufacturers are increasingly turning to alternative stabilizers that offer comparable performance but without the potential health risks.

So, PVC stabilizers are important additives that help improve the reliability and service life of PVC products in various industries. By protecting PVC from degradation caused by heat, UV rays and other environmental factors, stabilizers ensure that PVC products continue to perform effectively for their intended use. As the demand for durable and sustainable materials continues to grow, the role of PVC stabilizers in promoting the widespread use of PVC remains as important as ever.

Post time: Jan-05-2024