PVC stabilizers play a vital role in the manufacturing of calendered sheet materials. They are a type of chemical additives that are mixed into materials to enhance the thermal stability, weather resistance, and anti-aging properties of calendered sheets. This ensures that calendered sheets maintain stability and performance across various environmental and temperature conditions. The primary applications of stabilizers include:

Enhanced Thermal Stability: Calendered sheets may be exposed to high temperatures during production and usage. Stabilizers prevent material decomposition and degradation, thereby extending the lifespan of calendered sheets.

Improved Weather Resistance: Stabilizers can enhance the weather resistance of calendered sheets, enabling them to withstand UV radiation, oxidation, and other environmental impacts, reducing the effects of external factors.

Enhanced Anti-Aging Performance: Stabilizers contribute to preserving the anti-aging performance of calendered sheets, ensuring they maintain stability and functionality over extended periods of use.

Maintenance of Physical Properties: Stabilizers help maintain the physical characteristics of calendered sheets, including strength, flexibility, and impact resistance. This ensures that the sheets remain stable and effective during use.

In summary, stabilizers are essential in the manufacturing of calendered sheet materials. By providing necessary performance enhancements, they ensure that calendered sheets perform exceptionally well in different environments and applications.

|

Model |

Item |

Appearance |

Characteristics |

|

Ba-Cd-Zn |

CH-301 |

Liquid |

Flexible & Semi Rigid PVC Sheet |

|

Ba-Cd-Zn |

CH-302 |

Liquid |

Flexible & Semi Rigid PVC Sheet |

|

Ca-Zn |

TP-880 |

Powder |

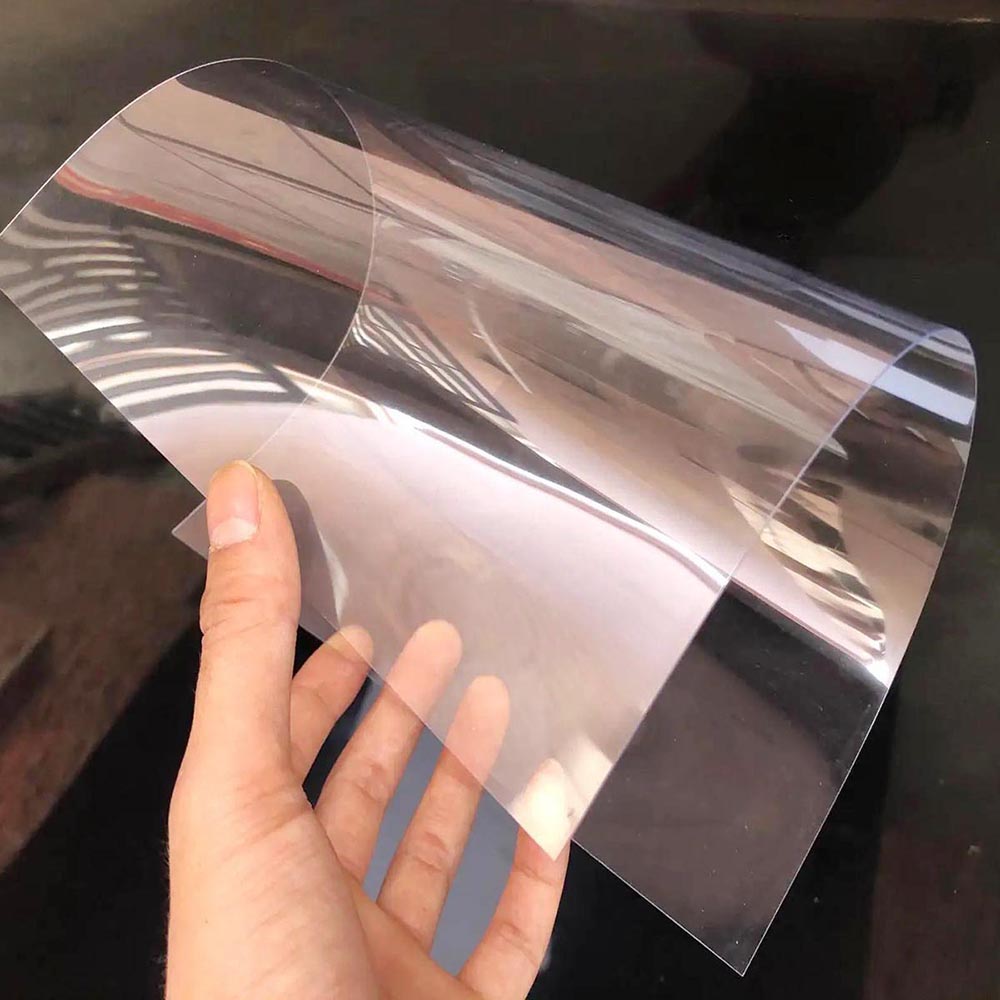

Transparent PVC sheet |

|

Ca-Zn |

TP-130 |

Powder |

PVC calendering products |

|

Ca-Zn |

TP-230 |

Powder |

PVC calendering products |